General Industrial | Paralloy & Firth Vickers

Our versatile facilities supply world-class components

to a broad variety of industries

Markets

General Industrial | Paralloy & Firth Vickers

Our versatile facilities supply world-class components to a broad variety of industries. We encourage customers to discuss their production and design challenges; simply describe your problem and we’ll provide the answer. We work closely with our clients to understand their requirements before producing a timely solution that comprehensively meets their needs.

Our engineers will work with you to provide new solutions, which can improve your reliability in service quality and reduce your overall costs.

General Industrial | Paralloy & Firth Vickers

Products & Solutions

General Industrial | Paralloy & Firth Vickers

Industrial Process Equipment

The nature of the centrispun process means that we can offer tubes, rings, and detailed shapes for applications within centrifuges, paper mills, materials handling, and the drink and food processing industries.

Materials Capabilities Talk to our experts

General Industrial | Paralloy & Firth Vickers

Furnace Components

Our unique casting process allows us to produce bespoke materials that can be used in high-temperature environments. Contact us with your requirements today to learn how we can assist you with a timely solution.

Materials Capabilities Talk to our experts

General Industrial | Paralloy & Firth Vickers

Pumps and Valves

We provide an extensive range of stainless steels, duplexes, and high-alloy materials, including nickel-based alloys. As a result, we offer solutions that cover the demanding nature of pump and valve requirements, including resistance to wear, oxidisation, and acidity. Our capabilities cover all areas of heavy-duty industrial applications and cover bespoke solutions in hardened and tempered, solution annealed, or hardened conditions.

Materials Capabilities Talk to our experts

General Industrial | Paralloy & Firth Vickers

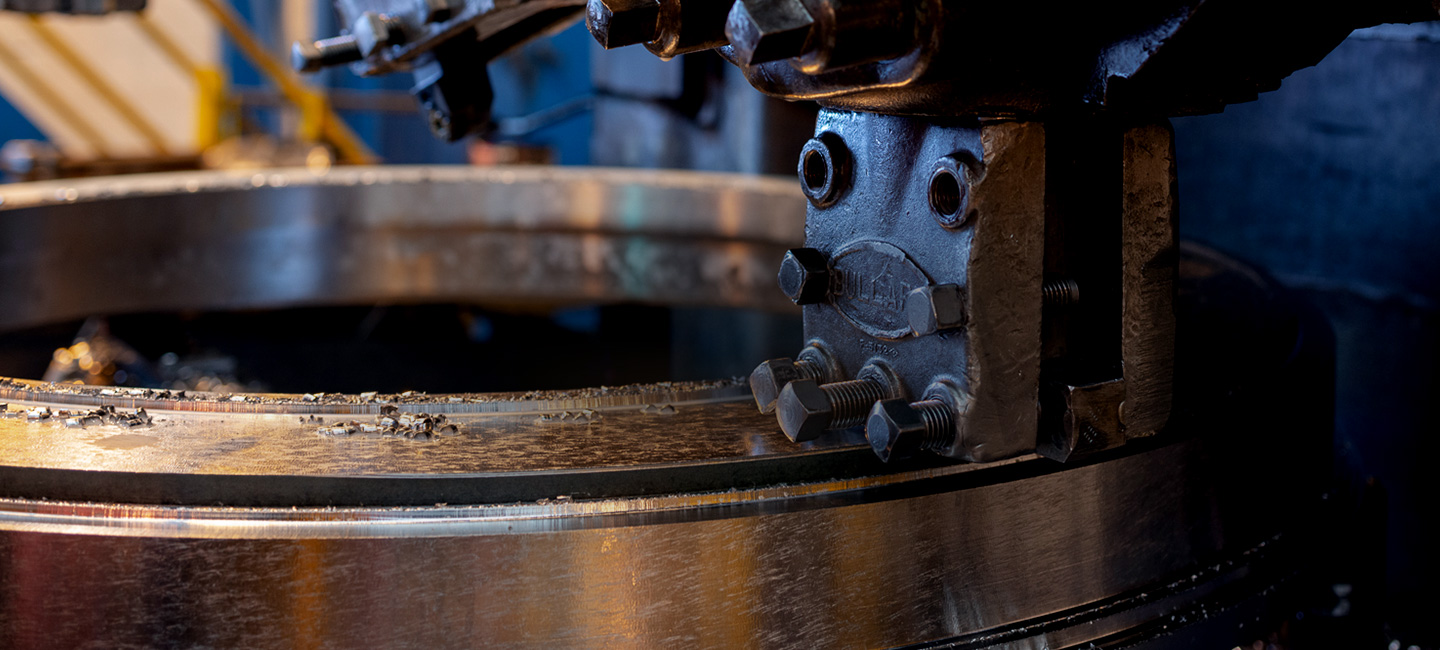

Centrifugal Components

Using an advanced centrispinning process, we are able to offer tubes, rings, and shapes in a wide range of materials. These are produced with short lead-times, particularly compared to mills, making centrifugal components an ideal solution.