The ingenuity of our materials is what makes the quality and performance of our products possible.

We have developed materials with wide-ranging capabilities suitable for a broad number of applications. By working with metallurgical specialists, and furnace designers we have been able to create these ground-breaking new materials

that resolve complex industrial challenges adding value to our customer’s businesses, every day.

We also apply our expertise in materials chemistry to design and synthesise bespoke solutions that meet our customers’ exact requirements.

Research & Development

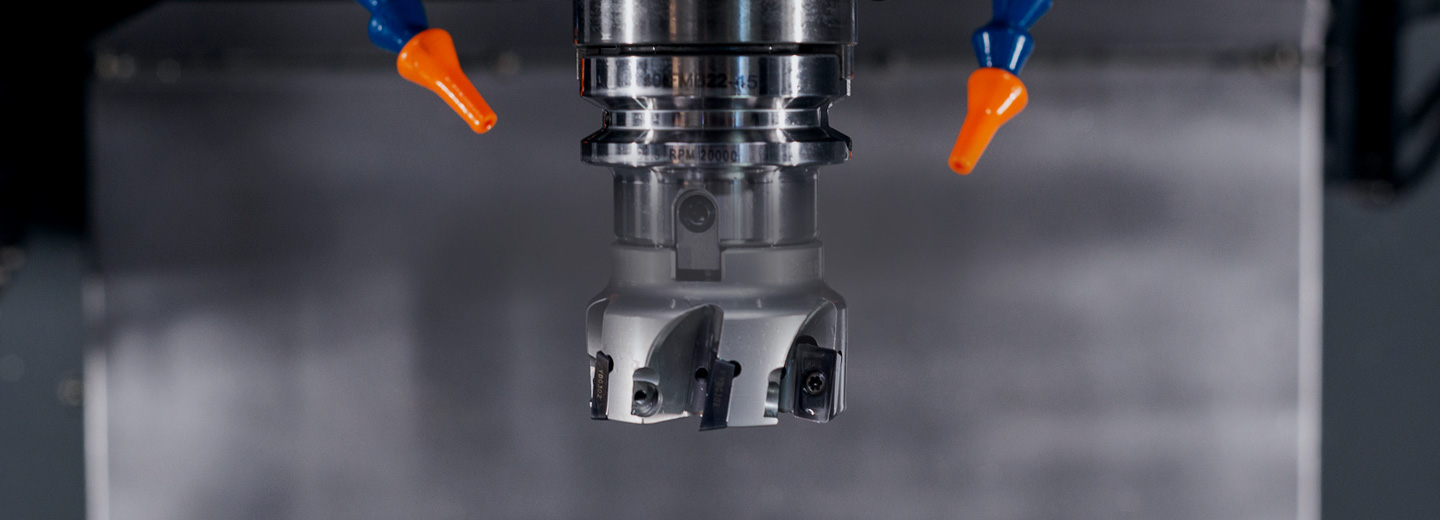

At the cutting-edge

We undertake cutting-edge research and development to deliver products that provide high operating performance and reliability, even in the most demanding of conditions.

By carefully managing the chemistry and tolerance of our solutions, we are able to provide products with world-class corrosion resistance and durability that perform exceptionally in the most extreme environments imaginable.

Materials

Paralloy Materials

| Alloy | Common Reference | Typical Upper Temp Limit | Applications | Nominal Composition % | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steam Reforming | |||||||||||||||||||

| Deg C | Deg F | Ammonia | Methanol | Hydrogen | Outlet Manifold | Ethylene (Radiant Tubes) | Transfer Lines | Direct Reduction | Ethylene Dichloride Coils | Tube Hangers, supports, guides | PEP Tube profile | C | Cr | Ni | Nb | W | Other | ||

| H39WM+ | Microalloy | 1100 | 2012 | 0.4 | 25 | 35 | 1.2 | Micro additions | |||||||||||

| H39WMR | Microalloy | 1100 | 2012 | 0.4 | 25 | 35 | 1 | Si 0.8, Mn 1, plus add | |||||||||||

| H39WM | "HP MicroAlloy" | 1100 | 2012 | 0.4 | 25 | 35 | 1 | ||||||||||||

| CR32W | "Alloy 800 CT15C" | 1000 | 1832 | 0.1 | 20 | 32 | 1 | - | |||||||||||

| H20 | "HK40" | 950 | 1742 | 0.4 | 25 | 20 | - | ||||||||||||

| H21 | "HK40 Si" | 1025 | 1877 | 0.4 | 25 | 20 | Si | ||||||||||||

| OPTIM-AL | Aluminium Alloy | 1200 | 2192 | 26 | 43 | 0.8 | Ti 0.1, Al3.0-5.0 | ||||||||||||

| H46M | "35/45 Microalloy" | 1150 | 2102 | 0.4 | 35 | 45 | 1 | - | Ti+Zr | ||||||||||

| H39WM | "HP MicroAlloy" | 1135 | 2075 | 0.4 | 25 | 35 | 1 | ||||||||||||

| H48T | "22H" | 1200 | 2192 | 0.5 | 28 | 48 | - | 5 | Si | ||||||||||

| H34CT | "HP W mod" | 1150 | 2102 | 0.45 | 25 | 35 | - | 4 | |||||||||||

| CR46M | "35/45 Microalloy" | 1070 | 1958 | 0.1 | 25 | 45 | 1 | ||||||||||||

| CR39W | "HP Nb Mod LC" | 1050 | 1922 | 0.1 | 25 | 35 | 1 | ||||||||||||

Materials

Firth Vickers Alloys

Martensitic heat & wear resistant high strength steels

| Alloy | Nominal Composition % |

Aisi Type / Common Name |

Can be supplied to specs | ||||

|---|---|---|---|---|---|---|---|

| BS | ASTM | W.No. | UNS | AMS | |||

| FV 2.5 Ni | 0.10 C, 2.5 Ni, Bal Fe | ASTM A 352, Grade LC2 | 1.5636 | ||||

| FV 9CrMo | 0.12 C, 9.0 Cr, 1.0 Mo, 0.0075 Nb, 0.22 V, 0.05N | ||||||

| FI & FV 410 | 0.10 C, 12.5 Cr | 410 STAINLESS | 3100 410 C21 | A217, A487, 743 CA15 | 1.4006 | J91150 | |

| FG | 0.20 C, 12.5 Cr | 420 STAINLESS | 3146 ANC 1B 3100 420 C24 | A743 CA40 | 1.4027 | J91153 | |

| FH | 0.38 C, 12.5 Cr | ||||||

| FHM | 0.8 C, 17.0 Cr, 0.5 Mo | 440B | 1.4122 | ||||

| S 80 | 0.14 C 17.0 Cr, 2.0 Ni | ||||||

| FV 507 | 0.12 C, 11.0 Cr, 0.8 Ni, 0.7 Mo, 0.3 Nb, 0.15 V | 1.4492 | |||||

| FV 681 | 0.12 C, 11.5 Cr, 3.0 Ni, 1.8 Mo, 2.0 Co, 0.3 V | JETHETE M190 | |||||

| 13/4 | 0.06 C, 12.0 Cr, 4.0 Ni | 3100 425 CII | A487 A743 CA6NM | 1.4313 | J91540 | ||

| 17/4 PH | 0.05 C, 16.5 Cr, 4.0 Ni, 3.0 Cu, 0.25 Nb | 17/4 PH | CB-7Cu | 1.4542 | J92180 | 5398 | |

| FV520B | 0.06 C, 14.5 Cr, 5.0 Ni, 2.0 Mo, 2.0 Cu | 5396 | |||||

| FV 535 | 0.09 C, 10.5 Cr, 0.50 Ni, 0.75 Mo, 0.20 V, 5.3 Co, 0.30 Nb, 0.02 N, 0.01 B | FV 535 | |||||

| M 152 | 0.10 C, 12.0 Cr, 2.5 Ni, 1.75 Mo, 0.35 V | JETHETE MI52 | 1.439 & 4939 | ||||

| Alloy | Nominal Composition % |

Aisi Type / Common Name |

Can be supplied to specs | ||||

|---|---|---|---|---|---|---|---|

| BS | ASTM | W.No. | UNS | AMS | |||

| FST Firth Stainless | 0.06 C, 18.0 Cr, 8.5 Ni | 304 STAINLESS | 3100 304 C15 3100 302 C25 | A351 CF8A A451 CPF8 | 1.4308 | J92600 | |

| FDP Firth Decay Proof | 0.10 C, 18.0 Cr, 8.5 Ni,0.16 Ti | 321 STAINLESS | |||||

| FSL Firth Stainless Low C | 0.03 C, 18.0 Cr,8.5 Ni | 304L STAINLESS | 3100 304 C12 | A351 A743 A744 CF3 A451 CPF3 | A351 A743 A744 CF3 A451 CPF3 | J92500 | |

| FCB -347E Firth Columbian Bearing | 0.08 C, 18.0 Cr, 9.0 Ni, 8XC TO 1.5 Nb | 347 STAINLESS | CF-8C | 1.4815 | J92710 | ||

| FML | 0.03 C,18.5 Cr, 10.5 Ni, 2.5 Mo | 316 LOW C | |||||

| FMB 1 | 0.06 C,18.5 Cr, 10.5 Ni, 2.5 Mo, 8XC to 1.0 Nb | 318 STAINLESS | |||||

| FMB2 Firth Moly Bearing | 0.06 C,18.5 Cr, 10.5 Ni, 2.5 Mo | 316 STAINLESS | 316C16 | CF-8M | J92901 | ||

| FMB 4 | 0.05 C, 17.5 Cr, 13.5 Ni, 2.25 Mo, 0.25 S | 316 FREE MACHINING | 3100 316 C16F | ||||

| FMB 5 | 0.08 C, 19.0 Cr, 9.0 Ni, 2.5 Mo, 8XC TO 1.0 Nb, 0.25 S | 318 FREE MACHINING | |||||

| FMB M | 0.10 C, 18.75 Cr, 8,5 Ni, 2.5 Mo, 1.0 Nb | 318 | |||||

| FMS | 0.10 C, 20.0 Cr, 9.0 Ni, 2.75 Mo, | ||||||

| FMX | 0.08 C. 23.5 Cr, 9.0 Ni, 3.5 Mo, | 1.4572 | |||||

| FMN | 0.06 C, 25.0 Cr, 5.0 Ni, 2.0 Mo, 0.20 N | A890 G3A | |||||

| 22/6 Mo | 0.03 C, 22.0 Cr, 5.5 Ni, 3.0 Mo, 0.20 N | DUPEX STAINLESS | A 890 CD3MN 4A | 1.4462 | J92205 | ||

| FV 27/5 | 0.06 C, 27.0 Cr, 6.5 Ni, 0.15 N | 1.4460 1.4347 | |||||

| FV 27/5 HC | 0.40 C, 27.0 Cr, 4.5 Ni, | 1.434 | |||||

| VIKRO 100 | 0.10 C, 16.5 Cr, Bal Ni, 17.0 Mo, 4.5 W, 0.30 V, 5.0 Fe | Hastalloy C | 3146 ANC 16 A494 CW-12MW | ||||

| VIKRO 200 | 0.02 C, 16.0 Cr, 65.0 Ni, 16.0 Mo, 0.5 W | Hastalloy C4 | A 494 CW 2M | ||||

| VIKRO 263 | 0.06 C, 20.0 Cr, 50.0 Ni, 6.0 Mo, 20.0 Co, 2.0 Ti, 0.5 Al | Nimonic C263 | 2.4672 | ||||

| VIKRO 276 | 0.03 C, 16.0 Cr, 60.0 Ni, 16 Mo, 2.0 Co, 4.0 W | Hastalloy C276 | |||||

| FV904 | 0.03 C, 20.0 Cr, 25.0 Ni, 4,5 Mo, 1.5 Cu | 904 | |||||

| NMX | 0.50 C, 5.0 Cr, 12.5 Ni, 5.5 Mn, 2.0 Cu, 0.30 V | NON MAGNETIC STAINLESS | |||||

| Alloy | Nominal Composition % |

Aisi Type / Common Name |

Can be supplied to specs | ||||

|---|---|---|---|---|---|---|---|

| BS | ASTM | W.No. | UNS | AMS | |||

| HRC1 | 0.20 C, 22.0 Cr, 12.0 Ni | ||||||

| HRCM | 0.20 C, 22.0 Cr, 12.0 Ni, 3.0 W | 309 + W | 3146 ANC6B | ||||

| 25/20 | 0.35 C, 25.0 Cr, 20.0 Ni | 310 | 1.4841 | ||||

| FV 25/12 | 0.15 C, 25.0 Cr,14.0 Ni | 309 | 3100 309C30 | A351 CH20 | 1.4833 | ||

| FS 60 | 0.10 C, 17.0 Cr, 8.5 Ni, 8.0 Mn, 4.0 Si, 0.1 Co, 0.13 N | NITRONIC 60 | A351 & A743 CF10S Mn N | ||||

| FS 50 | 0.05 C, 21.5 Cr, 12.5 Ni, 5.0 Mn, 2.0 Mo, 1.5 Nb, 0.30 N | NITRONIC 50 | A743 CG6MnN | S20910 | |||

| FV 539 | 0.03 C, 21.0 Cr, 9.0 Ni, 3.60 Mo, | HIGH STRENGTH 317 | CG 3M CG 8M | ||||

| FV 254 D | 0.03 C, 20.0 Cr, 29.0 Ni, 2.5 Mo, 3.5 Cu | CARPENTER 20 | BS3100 332 C11 | A743 CN7M | J95150 | ||

| FV 540 | 0.03 C, 17.5 Cr, 13.5 Ni, 4.2 Mo, 0.16 N | 317L | 317C16 | CG-8M | 1.4439 | J93000 | |

| FV 16/16Nb | 0.06 C, 16.5 Cr, 16.5 Ni, 2.0 Mo, 0.70 Nb | 1.4981 | |||||

| VIKRO 3 (37/18) | 0.4 C, 18.0 Cr, 36.0 Ni, 2.0 Si | 330 | A297 HT | ||||

| VIKRO 7 | 0.10 C, 19.0 Cr, 80.0 Ni, 0.3 Ti | MNIMOCAST 75 | 3146 ANC 8 | ||||

| VIKRO 9 | 0.10 C, 19.0 Cr, BAL Ni,17.0 Co, 1.8 Ti, 1.4 Al | 3146 ANC 10 | |||||

| VIKRO 20 | 0.10 C, 22.0 Cr, 47.0 Ni, 9.0 Mo, 1.5 Co, 0.60 W | Hastalloy X | 5390 | ||||

| VIKRO 80 | 0.08 C, 19.0 Cr, 75.0 Ni, 2.0 Ti, 1.5 Al | 3146 ANC 9 | 2.4952 | ||||

| VIKRO 155 | 0.12 C, 21.0 Cr, 20.0 Ni, 20.0 Co, 3.0 Mo, 1.0 Nb, 2.5 W, 0.15 N | MULTIMET - N155 | |||||

| VIKRO 617 | 0.08 C, 22.0 Cr, 9.0 Mo, Bal Ni, 12.0 Co, 1.0 Al, 0.40 Ti, | ||||||

| VIKRO 625 | O.O8 C, 22.0 Cr, 60.0 Ni, 9.0 Mo, 3.6 Nb, 0.30 Ti, 0.30 Al | Inco 625 | A494 CW-6MC | 2.4854 | N26625 | 5402 | |

| VIKRO 825 | 0.04 C, 22.5 Cr, 41.0 Ni, 3.0 Mo, 2.5 Cu, 1.0 Nb | INCO 825 | A 494 CU5MCuC | N08826 | |||

| Alloy | Nominal Composition % |

Aisi Type / Common Name |

Can be supplied to specs | ||||

|---|---|---|---|---|---|---|---|

| BS | ASTM | W.No. | UNS | AMS | |||

| R100 | 0.015 C, 18.0 Cr, 8.0 Ni, 4.75 B | Boron Containing Nuclear Tube | |||||

| CHROME IRON CI5 | 1.8 C, 14.2 Cr, 0.02 Ni, 0.4 Mo, | ||||||

| VESUVIUS 1 | 0.30 C, 27.0 Cr, 2.0 NI | A743 CC-50 | |||||

| VESUVIUS 2 | 1.0 C, 27.0 Cr, 2.0 NI | 3100 452 C11 | |||||

| VESUVIUS 3 | 1.5 C, 27.0 Cr, 2.0 NI | 3101 452 C12 | |||||

| CARBON STEEL | 0.2 C 0.55 Si, 1.0 Mn | 3100 AL1 | |||||